Hydrogenation can modify the properties of organic energy sources, tailoring them to meet specific quality standards. This process involves adding hydrogen to the double bonds within organic molecules, thereby altering the substances' physical characteristics. Moreover, hydrogenation serves to reduce the oxygen content of biomass pyrolysis oils, enabling their use as components or precursors for biofuels. For plastic pyrolysis oils, hydrogenation, often coupled with hydrocracking, aims to remove undesirable heteroatoms, particularly nitrogen, oxygen, and sulfur. Hydrogenation reactions occur on the active sites of appropriate catalysts.

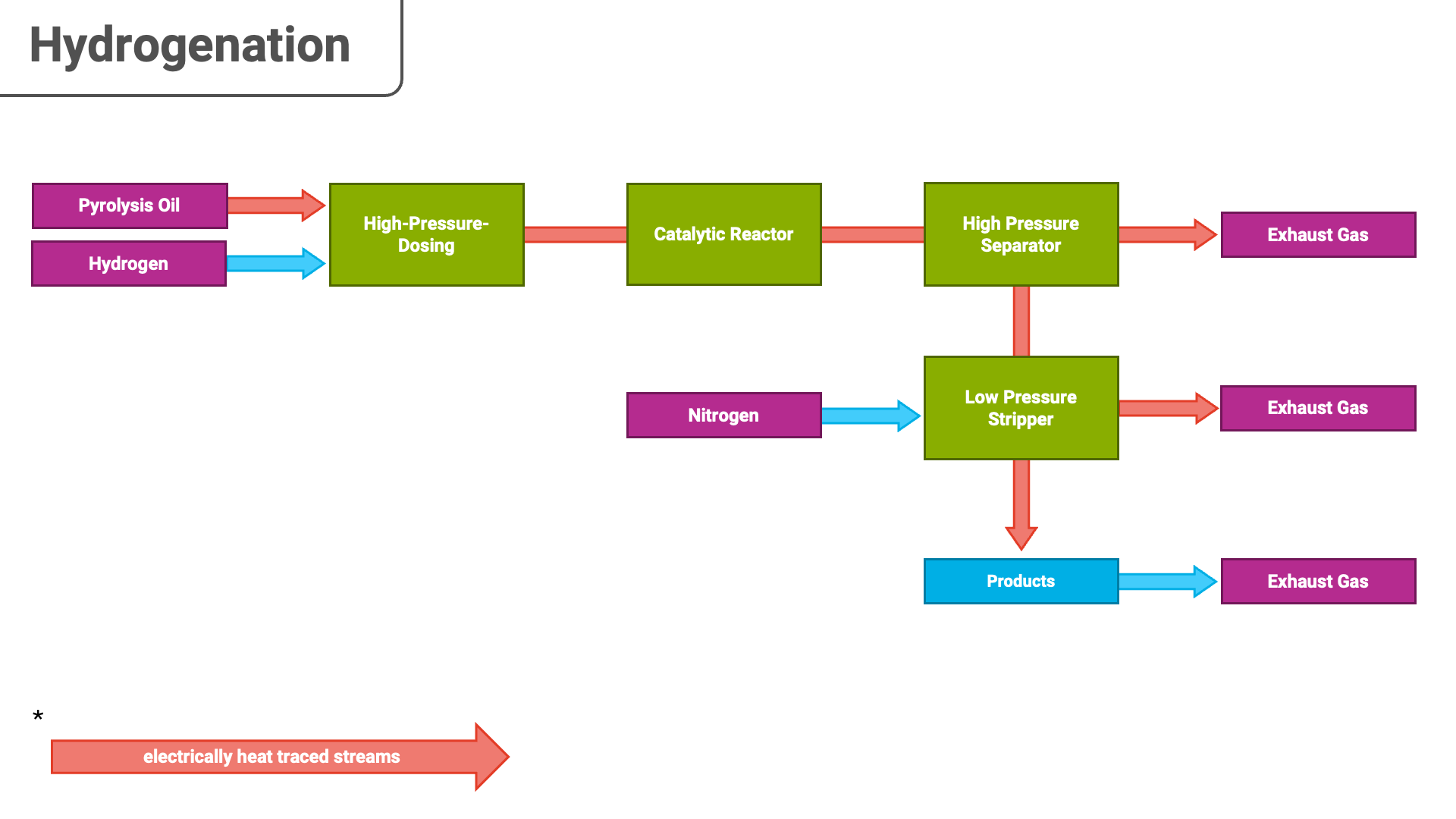

Our hydrogenation unit facilitates the continuous evaluation of catalyst materials for the hydrogenation of diverse feedstocks under controlled, reproducible reaction conditions. To ensure the safe execution, thorough documentation, and comprehensive analysis of organic feedstock hydrogenation, the unit comprises several subsystems. These subsystems manage feedstock introduction, handling, and precise dosing, and include the hydrogenation reactor itself, a dedicated sampling and analysis station, and product handling systems.

Within the Carbon Cycle Lab's research initiatives, this hydrogenation unit will be employed to process high-boiling point intermediate products – generated at various points within the Energy Lab – into commercially viable energy carriers, fuels, or chemical industry precursors. Furthermore, it will enable the advancement of hydrogenation processes and the catalysts utilized, driving innovation in this critical technology.