Fast pyrolysis is specifically optimized to maximize the production of liquid condensates, commonly known as pyrolysis oils, as the primary product. This process efficiently transforms biomass into an energy-dense form that is easier to handle and store. Furthermore, fast pyrolysis offers the potential to achieve negative CO2 emissions, thereby offsetting unavoidable greenhouse gas emissions from other sectors. Pyrolysis oils are currently utilized as a fuel source for heat generation in industrial steam boilers. However, they can also be processed into transportation fuels through co-feeding in an existing refinery or directly using dedicated catalytic processes. Fuels and basic chemicals can also be produced through gasification – via the synthesis route – which also allows for the utilization of the coke generated during pyrolysis.

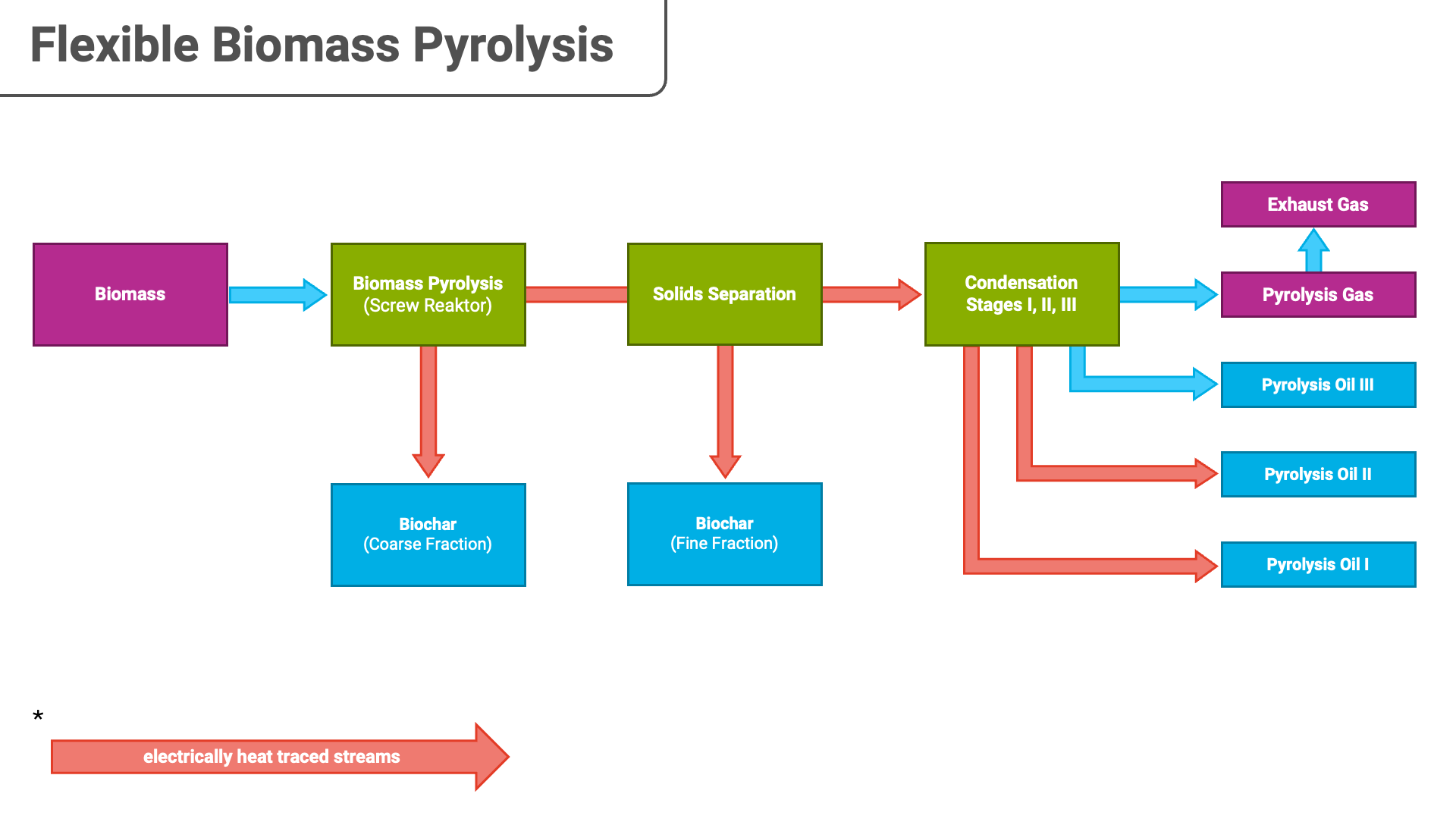

At the Carbon Cycle Lab, fast pyrolysis is conducted in a twin-screw mixing reactor. Within this reactor, shredded biomass feedstock is rapidly brought into contact with a circulating, hot heat transfer medium and heated to reaction temperatures, typically around 500 °C. Following thermal decomposition of the feedstock within mere seconds, the resulting pyrolysis products are separated from the heat transfer medium and rapidly quenched. This process yields liquid pyrolysis condensates (pyrolysis oils), ash-containing biochar (coke), and fuel gas.

Biomass pyrolysis efforts at our lab are focused on generating application-driven pyrolysis products from biogenic agricultural and forestry residues, aligning with relevant biorefinery strategies. This also encompasses achieving negative CO2 emissions through biochar production or CO2 capture within biorefinery systems. Additionally, research is underway to explore synergistic opportunities with emerging hydrogen and electricity-based economies.

Insights gained from operating the bioliq® pilot plant (500 kg/h biomass) and a technical-scale fast pyrolysis plant are currently being applied to the design and construction of a new pilot plant (5 kg/h). This new facility will enable testing of novel process configurations, plant components, operating parameters, and advanced measurement technologies at Technology Readiness Level (TRL) 5.

Operating parameters

- Educt = up to 5 kg/h

- Products = solids, condensates, fuel gas

- Operating pressure = atm

- Operating temperature = 500 °C

- Plant size = 5.0 x 5.0 x 4.5 m

Team Leader/ Principal Investigator Pyrolysis